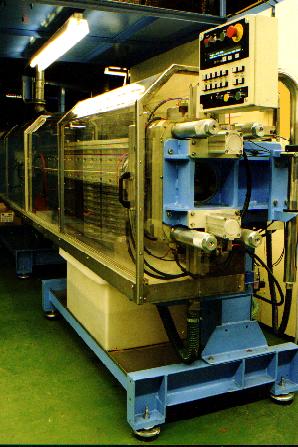

Thomas Watts Machines & Controls Ltd have been involved in designing and building

equipment for metal bellows manufacture since 1985

We have pioneered the development of elastomer forming techniques in the production

of high volume automotive exhaust bellows and engine connector components, (E.G.R. tube, secondary air pipes, etc).

We also design and built rolling machines and hydroforming equipment for forming

bellows from Ø12.0mm bore to 2000mm bore. Again we have used our expertise and

experience to develop unique solutions to the demands for increasing forming

depth and the limits of material elongation.

|

|

|

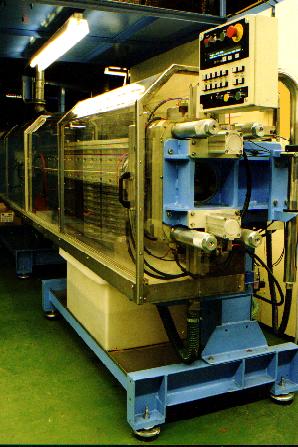

The strength of our designs lie in our ability to combine sound mechanical engineering

together with electrical / electronic engineering to produce cost effective, efficient,

reliable and versatile machines which are capable of producing a wide variety of products

We have made machines to produce bellows for a diverse range of industry sectors including

automotive, HVAC, process plant, aerospace and nuclear.

Customer's requirements are clearly identified through initial discussions,

site visits, machine specifications and preliminary drawings.

This information is used to produce the most cost effective, durable and

energy efficient solution.

We are committed to meeting our customers needs, on-time, on-budget and with

the most efficient solution. All our machines and controls are designed to EU

standards and are supplied CE marked with full documentation.

The majority of our products are exported to bellows makers throughout the World.